When I made to choice to model the Reading, I knew I had two choices, either have my modeling time after the last of steam or I was going to have to build some steam locomotives. There has not been many brass models imported in O scale of Reading steam locomotives. One reading fan suggested “buying a bunch of T-1’s and model 1956 because nothing else has been imported.”

When I was focused on the Elmira Branch of the PRR, I was also focused on 1956 as the date to model. When I first made the choice to model the Reading, I shifted my focused time period to 1953. All of the first generation diesel locomotives I liked were on the roster. And there were only a few Steam locomotive classes left running.

Well as luck would have it, I was able to trade some of my surplus PRR equipment for an SGL Reading G3. They only lasted on the line until the Summer of 1952 and then they were bumped from the King Coal by a pair of GP7’s. I’ve read that they lasted until September of that year even though the GP7’s which replaced them arrived in July. After that point the G3’s were transferred to South Jersey to run out their service life on the PRSL.

So that has set my time to the Summer of 1952.

Steam Classes

Left on the roster in 1952 were I9-sc’s, I10’s, K1-sd/e’s, N1-sd’s, G2-sa’s, G3’s and T-1’s.

The T-1‘s do not seem to show up in the photos West of Tamaqua until 1956-1957. They ran through the mainline to Pottsville and into Saint Clair. There is a really nice O Scale model of a T-1 done by Overland back in the 1990’s. There was also a nice Bob Jones’ Kit for a T-1 that was produced before the Overland run. The finding of a nice Overland T-1 has prompted the move of modeling location to Schuylkill Haven on the line to Pottsville.

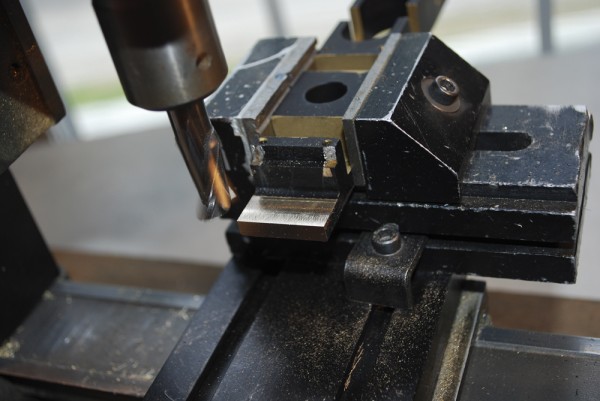

SGL imported the Reading G3 back around 2000. While not super detailed, it does have enough detail to be a good place to start. One arrived on my roster in a trade for some of that surplus PRR equipment.

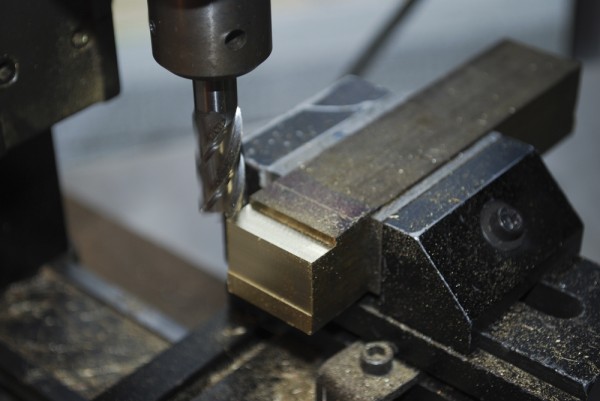

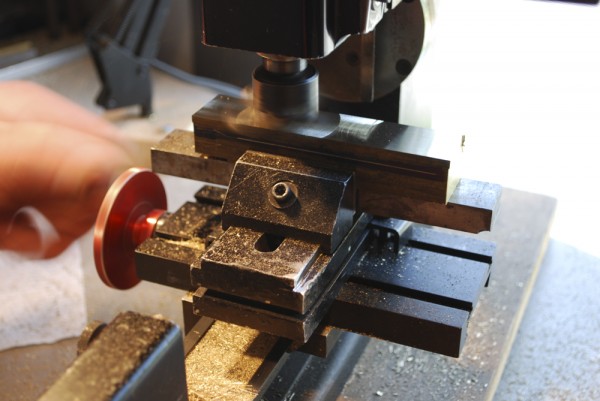

The N1-sd‘s, were built between 1917-1919 and are dimensionally close to a USRA 2-8-8-2. That is my starting point, I have a pair of Sunset N&W Y-3’s that are the going to become Reading locomotives.

The K1-sd/e‘s will have to be built. I found the the wheelbase is very close to that of the Sunset I1sa’s. With modifications to the Sunset frame, new boilers and new tenders, they will take shape.

The I10 uses almost the same wheel base as the PRR H10 so I plan to use the Central Locomotive Works H10 mechanism for this conversion.

The I9-sc was an I9 that was rebuilt with the running gear from the I10’s that became T1’s. So this too will use the Central Locomotive Works H10 mechanism for the conversion.

Diesel Classes

Seen in the photos from 1952 in the Shamokin Division were: Road Power EMD FT’s, F3’s, F7’s, ALCO FA1’s and Baldwin AS-16’s, Switchers were EMD NW2’s Baldwin VO-1000’s and DS4-4-1000’s.

EMD FT’s:

O Scale is blessed with a couple of choices for EMD FT brass models, Overland or Hallmark. The Hallmarks are detailed for Santa Fe units so they would require some correcting. But they usually show up at good prices at the shows. Overland are a newer model imported in the 90’s and the details are much cleaner but they cost a little more. I was lucky to find a pair at a very good price.

MTH also makes a 3-rail version of an EMD FT, but it is not a scale model. I owned a pair, so I was able to see and measure them first hand.

EMD F3 & EMD F7:

There have been a number of O scale EMD F3 & F7 models available both as kits and brass imports. I am using a combination of Overland F3’s and P&D F3’s and F7’s.

ALCO FA-1’s:

There are again a number of options here in O scale. Central Locomotive Works has made brass kits for them since before I was born. Key is about to import them, but their price point is not in my hobby budget. Overland has imported them in the past and that is what I have on my shelf. Also Custom Brass and Sunset both have imported them in the past. I was going to use the Custom Brass models until I found an A-B-A set of the Overland models at a great price.

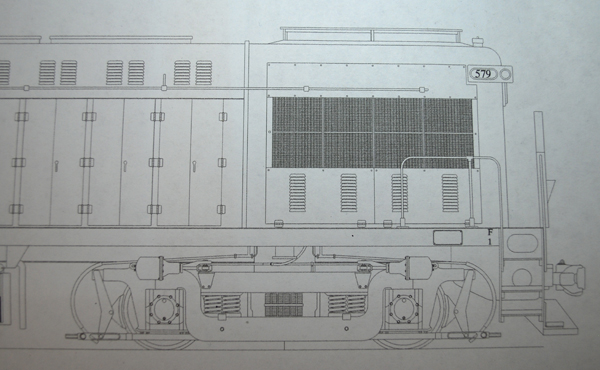

Baldwin AS-16’s:

The Overland AS-16 is THE option for modeling the Baldwin AS-16’s. The model was imported in the mid 90’s. They do show up at shows and on ebay every so often. So far the models I have found me in trades and one purchase. Overland produced both the early car body design and what modelers refer to as the ’53 body or high hood version.

Again, MTH has produced a 3-rail version that they call a Baldwin AS 616, but the hoods are too wide and too tall, they would require far too much work to correct them.

EMD NW2

All Nation has produced a white metal version almost as long as the prototype has existed. The All Nation model looks like 1940 technology. These have also been produced in brass by a couple of importers over the years.

I started building an NW-2 by combining an All Nation body on top of an Atlas SW9 frame. Life is way too short! I’m now looking for one of the brass imports to cross my path at a good price…..

Baldwin Vo-1000, DS4-4-1000:

I am using a pair of Car Works VO-1000’s and plan to back-date Rich Yoder’s S12 into the DS4-4-1000.

Weaver also make a nice model of the VO-1000 with curved insets in the walkways.

ALCO RS-3‘s and EMD GP7‘s:

While plentiful on the Reading, they did not venture into coal country much at this early date in freight service. That would change as time moves on and second generation diesels hit the roster.

Passenger service is a different story. The RS-3’s and the Gp-7’s did run in passenger service to Pottsville during this period.