A strange thing happened to me at the Chicago Show in 2019, a PRR B6sb followed me home. First is was priced so well, I couldn’t pass it up. That was mostly because it had a very bad paint job.

After spending some time being converted to Proto48 by Carl Jackson, this fine looking model came home with me on Saturday. During the time the model was with Carl it had the chance to take a bath in his stripping tank. It needed it!

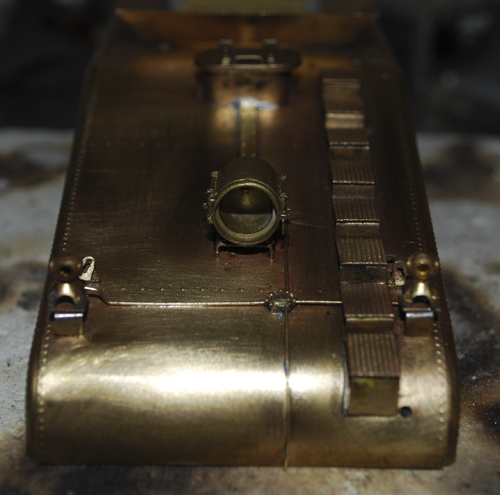

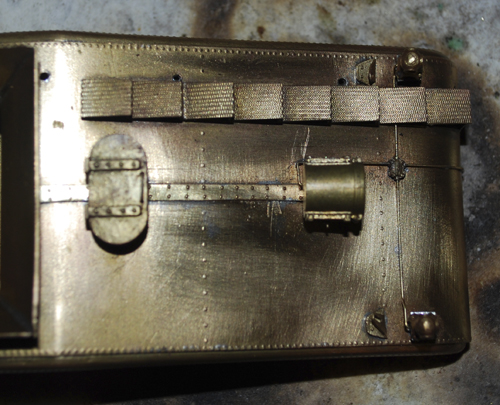

Now that all that ugly paint is gone, it revealed a couple of things the bad paint was hiding. It appears the previous owner had a mishap with the tender. The railings appear to have been damaged at one time. A repair attempt has resulted with too much heat being applied, which caused the rear tender deck to seperate from the side. There is also a little separation along the top rim of the coal bunker. So, I have some repair work to do before I can think about painting this model.

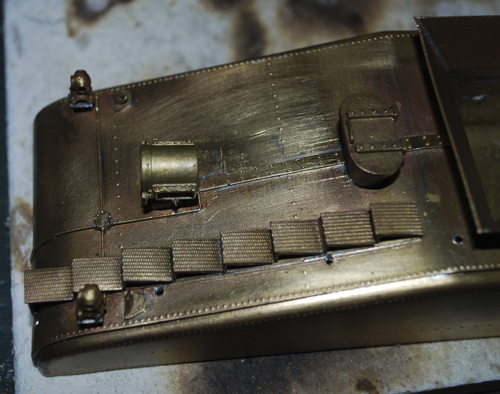

Next up was another model that came home from this past weekend’s show. It’s an RY Models Reading welded 55 ton twin hopper. It also is suffering from a case of bad paint. This time the issue was in the weathering attempt.

This is a good reason why you learn to paint and weather freight cars using a $20 Weaver car, not a brass model.

My first thought was to try to salvage the paint by just cleaning up the weathering. Better sense took over, rather than try to fix the bad weathering, I’ll just start over. So into the stripping tank for this one. I can say that with a little help from a toothbrush every few hours this model is now almost back to brass. I figure it will be done later today.